2D Code Solutions by MITech

2D barcodes are evolving rapidly, redefining traceability and transparency in supply chains. Project Sunrise 2027, led by GS1 standards, is driving this transformation—turning 2D barcodes into powerful tools for quality assurance, product information, and end-to-end traceability.

Our comprehensive solutions include advanced marking and coding technologies, smart software, vision systems, certified consumables, and comprehensive services. With precision 2D barcode printing, verification, and compliance built in, we help you enhance efficiency, reduce errors, and future-proof your operations.

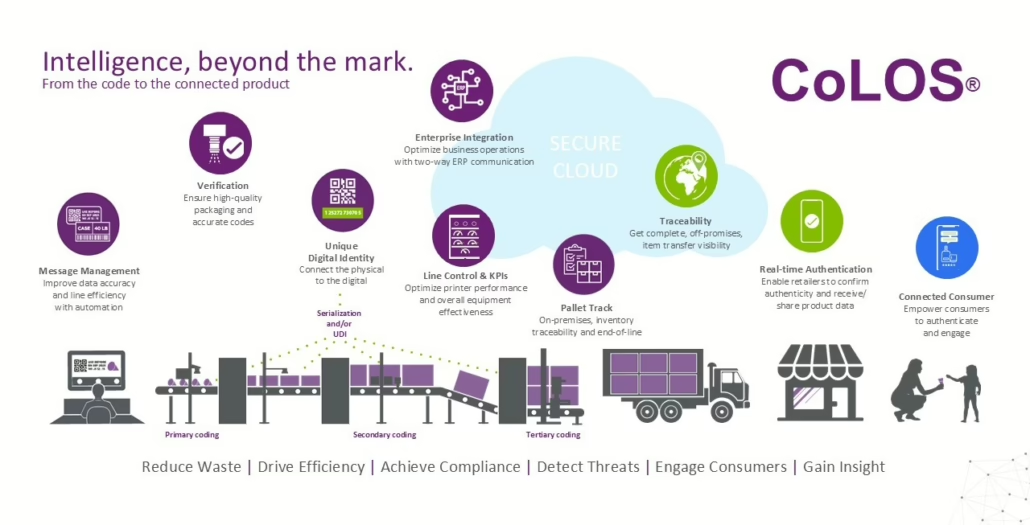

Data Management and Software Solutions

For a dynamic, serialised 2D code

Integrates with ERP/MES systems to centralise data, manage messages, and ensure GS1 compliance. It supports real-time data management,

message transmission to printers, and readability verification, reducing waste, improving efficiency, and protecting brand value.

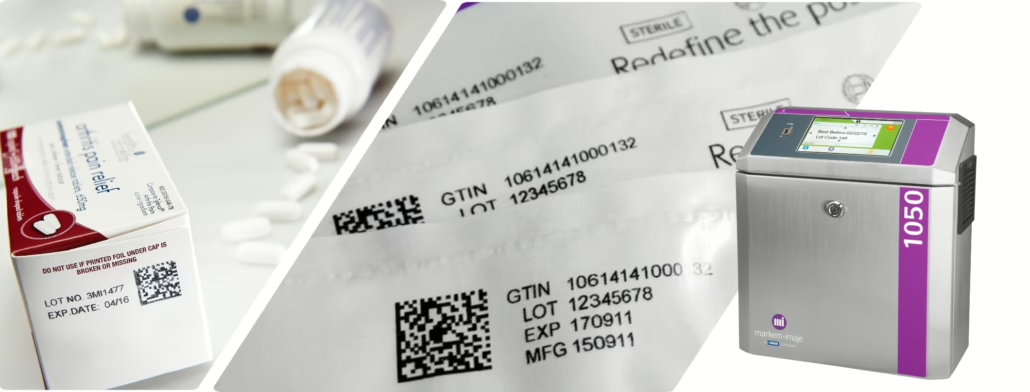

Coding Solutions

For sustainable 2D code printing

Print enhanced 2D codes with precision using our marking and coding solutions. GS1-compliant and designed to meet

substrate demands, our technologies embrace Industry 4.0 for speed, sustainability, and improved production.

Continuous Inkjet (CIJ)

KEY STRENGTHS

CIJ excels in high-speed coding on various surfaces. It is suitable where 2D barcodes are used for Lot/asset tracking and identification.

- Small footprint

- Marking on many types of media

- High printing speed possible

- Throw distance between the head and the material to be printed

- Marking easily controlled by vision

- In-line printing on the CPU / adapts to the line speed

- High speed and print rate

- Wide inks range

- Strong adaptation to almost all substrates

Laser

KEY STRENGTHS

Laser printing offers high-quality output and precise control, making it ideal for printing DataMatrix and QR codes with high density and resolution, suitable for applications requiring high quality durable and readable codes.

- Robust and very reliable technical solution

- No consumables needed = sustainable solution

- High-quality and permanent markings

- Marking easily controllable by vision

- Size of the QR Code/Optimal Data matrix

- Speed / number of prints good if appropriate support

Thermal Transfer Overprinting (TTO)

KEY STRENGTHS

TTO excels in printing high-quality DataMatrix and QR codes on flexible packaging and labels, offering durable and resistant codes, making it suitable for applications requiring long-lasting barcode readability.

- Specially designed for flexible films and labels

- Promotional coding function allows for unique coding on each pack

- High-quality 300 dpi printing

- Unlimited QR Code/Data matrix sizes

- Speeds of up to 1.800 millimeters per second (mm/s) and a pack rate of up to 455 packs per minute (PPM)

- Zero preventive maintenance

- Low capital costs

- No risk of perforating the material

Thermal Inkjet (TIJ)

KEY STRENGTHS

TIJ offers versatile variable data printing capabilities and flexibility on various surfaces, making it suitable for printing QR codes and other applications where high-quality text and images are required.

- Robust and very reliable technical solution

- Low capital investment

- Mainly films/bags and labels

- Quality markings and good hold

- Code verification via vision system

- TU (Traded Unit) Lookup scanner for automatic job select on merged lines

- Maximum speed around 200 m/min

- Very low maintenance

Touch Dry® Large Character Piezo

KEY STRENGTHS

- Speeds up to 182 m/min

- Wide capabilities to support 2D barcodes included stacked linear barcodes including Data Matrix, RSS linear, RSS composite, QR, RSS 14, RSS expanded, PDF 417

- High-quality GS1 compliant 2D codes

- Dynamic data

- No need to stop the line to add consumables

- Lower cost than labels

- Sustainable ink with no volatile organic compounds

- Solid Ink maintains high resolution unlike liquid ink which will spread on contact

- Print on a wide variety of substrates including corrugate, polystyrene, hard plastic, film, non-wovens

- Barcode printing up to 40 m/min

- No factory air needed

Print & Apply (P&A)

KEY STRENGTHS

Print and apply technology offers high accuracy, printing and applying labels with high-quality DataMatrix and QR codes, ideal for efficient and precise labeling in production lines.

- Wide capabilities to support 2D barcodes included stacked linear barcodes (QR code, Aztec code, Data Matrix and PDF417)

- 2D support via Dual Language Support allowing direct communication with ZPL emulation*

- Compliant ANSI grade A/B codes even at the highest application speed, at 300 dpi

- Over 155 packs per minute with variable and unique data

- High-speed application without no degradation of codes

- Capable of managing variable height or pack position

Vision System Solutions

For a verified 2D code

Verify 2D barcode readability, even in high-speed environments with damaged or occluded codes, guaranteeing data accuracy and packaging compliance.

High-Speed Barcode Reading (2D codes)

Maximise packaging manufacturing efficiency and throughput with Cognex fixed-mount barcode readers that deliver reliable code reading, even for damaged or challenging codes. Deploy GS1 2D barcode reading applications quickly and achieve faster ROI with an intuitive web-based setup.

Barcode Quality Grading

Ensure your supply chain partners are satisfied and avoid chargebacks due to poor code quality. Reliably grade barcodes to meet GS1 standards using Cognex image-based barcode readers, which offer built-in tools for precise diagnostics and maintaining high barcode quality.

Simultaneous Barcode and Text Code Reading

Improve line efficiency by verifying the quality of printed GS1 2D codes, text, and graphics while decoding 2D barcodes simultaneously with a single Cognex In-Sight vision system. Easy-to-follow online guided setup tools get your GS1 inspection applications into production faster and achieve quicker ROI.

Ready to Transition to 2D Code?

With seamless integration of marking and coding technologies, smart software, vision systems, certified consumables, and comprehensive services, we empower you to stay ahead. These systems ensure high-quality 2D barcode printing, verification, and compliance, enhancing production efficiency and minimising errors making Mitech – Your Vision for Tomorrow’s Coding and Traceability Solutions Today.