Package Leak Detection

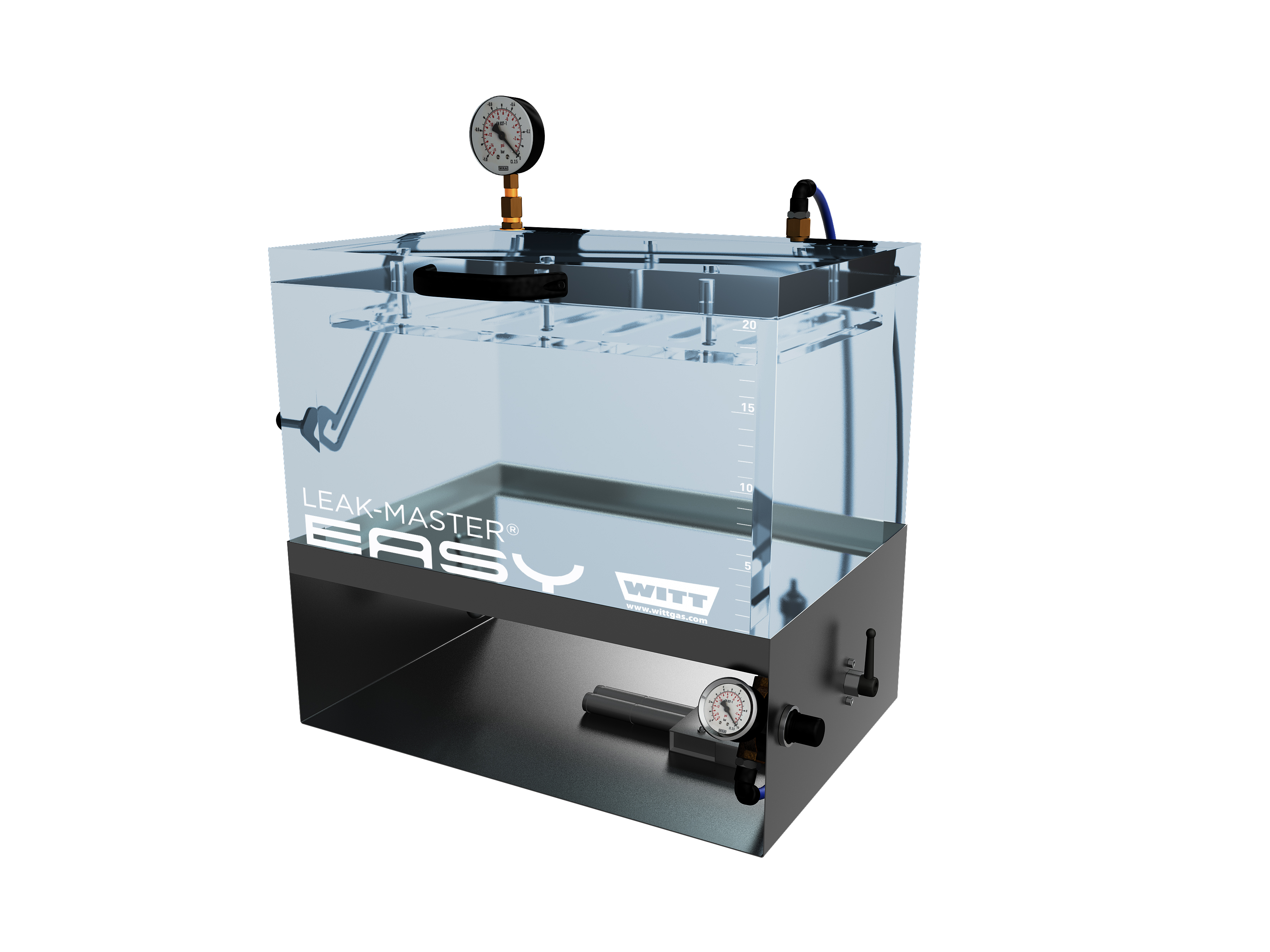

WITT package leak detector with bubble test

- economical and uncomplicated leak testing

- visual inspection allows localisation of the leak

- for all flexible and rigid kind of packaging

- easy-to-use intuitive operation

- short leak testing period (< 30 sec.)

Products and packages need to be leak-tight. And there is a single, simple and very effective way to test leak-tightness and seal integrity, heading the extensive range from WITT, offered by MITech.

LEAK-MASTER® EASY is a water-based leak detector. This leak detection technique enables identification of even the smallest of leaks, and testing of seal integrity without the use of trace gases.

This method of this leak detection, also known as the bubble leak test or bubble leak detection, is one of the eldest and most intuitive leak detection principles – the use of a water bath.

WITT is certified to ISO 9001 and ISO 22000

LEAK-MASTER® EASY is approved for food gases according to regulation (EG) No.1935/2004.

The LEAK-MASTER® EASY leak testers can be used for various ASTM-tests for the detection of leaks

Accessories:

- Control unit PLUS: portable controller with various predefined measurement programmes, also for documentation of your measuring results

- Vacuum testing set: for testing vacuum packaged products and products with low gas volumes

- AD100: calibrated pressure gauge with DKD/ DAkkS-certificate

- Vacuum holding valve: blocks the chamber after generation of vacuum. Perfect for longer test periods without permanent use of compressed air